BK101

Knowledge Base

Engineering - Design - Architecture

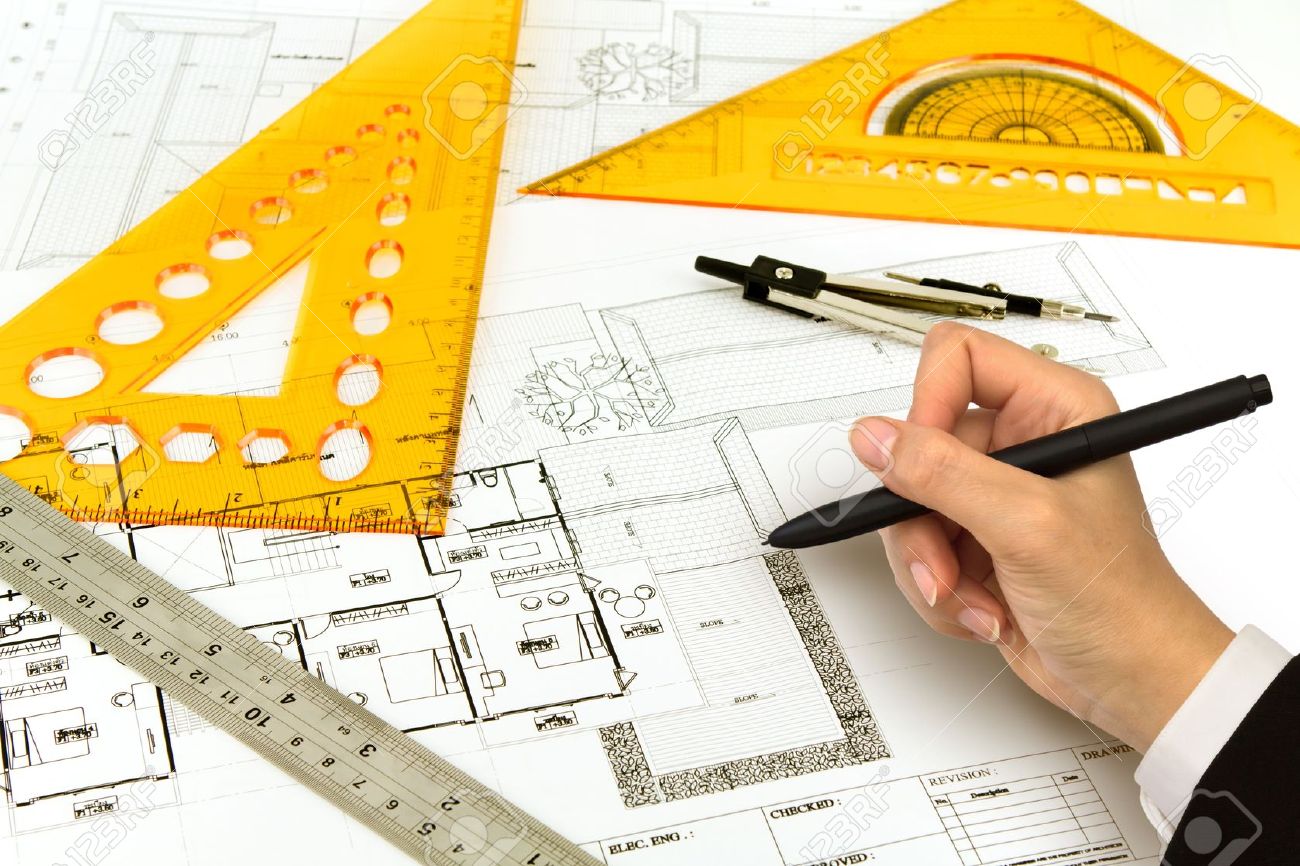

Engineering is the discipline dealing with the art or science of applying scientific knowledge to practical problems. Plan and direct a complex undertaking. Someone who can correctly calculate the load capacities of materials and assemble them correctly. Engineering is the application of mathematics, empirical evidence and scientific, economic, social, and practical knowledge in order to invent, innovate, design, build, maintain, research, and improve structures, machines, tools, systems, components, materials, and processes. The discipline of engineering is extremely broad, and encompasses a range of more specialized fields of engineering, each with a more specific emphasis on particular areas of applied science, technology and types of application.

Designing is

Planning to create something for a

specific role or purpose or effect. Create the design for;

create or execute in an

artistic or highly skilled

manner. Conceive or

fashion in the mind;

invent.

Designing is

Planning to create something for a

specific role or purpose or effect. Create the design for;

create or execute in an

artistic or highly skilled

manner. Conceive or

fashion in the mind;

invent. Engineering Marvels are a man-made artifacts or objects such as bridges, tunnels, skyscrapers or railways are feats of engineering that make you stare in awe and wonder at the process that led to their existence.

Reverse Engineering is the processes of extracting knowledge or design information from anything man-made, and then re-producing it based on the extracted information. The process often involves disassembling something like a mechanical device, or a electronic component, computer program, or biological, chemical, or organic matter, and then analyzing its components and workings in detail so that you may build something similar to it, or build something more advanced. Modeling.

Architecture is the discipline dealing with the

principles of design, construction and ornamentation of fine buildings.

Designing buildings and

environments with

consideration for their

esthetic effect.

Architecture is the discipline dealing with the

principles of design, construction and ornamentation of fine buildings.

Designing buildings and

environments with

consideration for their

esthetic effect.What are the differences between design, engineering and art? Can all 3 disciplines be combined without sacrificing health, science and sustainability?

How Architecture can Create Dignity for All: John Cary (video and text)

Environmental Science - Safety Engineering - Structural Engineering

"There's pretty and then there's practicable, but if you can make practicable pretty, then that's even better."

Practicable is something usable for a specific purpose. Capable of being done with means at hand and circumstances as they are.

Engineering Types - Branches of Engineering

Engineer designs materials, structures, and systems while

considering the limitations imposed by practicality, regulation, safety,

and cost. Math Skills Needed.

Engineer designs materials, structures, and systems while

considering the limitations imposed by practicality, regulation, safety,

and cost. Math Skills Needed.Engineering Branches (45 Types)

Electrical Engineering is a field of engineering that generally deals with the study and application of electricity, electronics, and electromagnetism.

Electronic Engineering is an electrical engineering discipline which utilizes nonlinear and active electrical components (such as semiconductor devices, especially transistors, diodes and integrated circuits) to design electronic circuits, devices, microprocessors, microcontrollers and other systems. The discipline typically also designs passive electrical components, usually based on printed circuit boards. Electronics is a subfield within the wider electrical engineering academic subject but denotes a broad engineering field that covers subfields such as analog electronics, digital electronics, consumer electronics, embedded systems and power electronics. Electronics engineering deals with implementation of applications, principles and algorithms developed within many related fields, for example solid-state physics, radio engineering, telecommunications, control systems, signal processing, systems engineering, computer engineering, instrumentation engineering, electric power control, robotics, and many others. The Institute of Electrical and Electronics Engineers (IEEE) is one of the most important and influential organizations for electronics engineers.

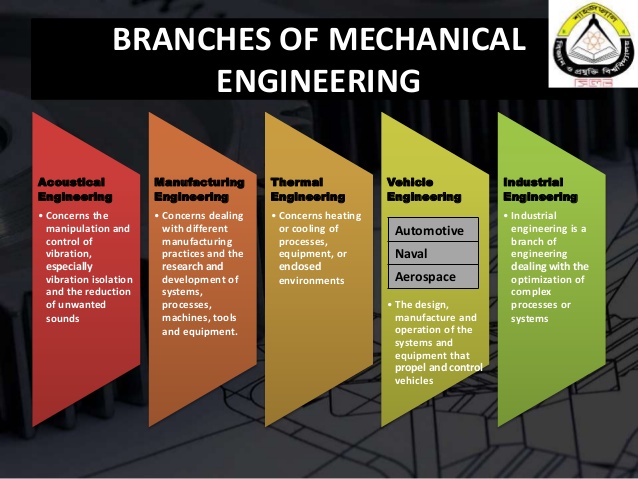

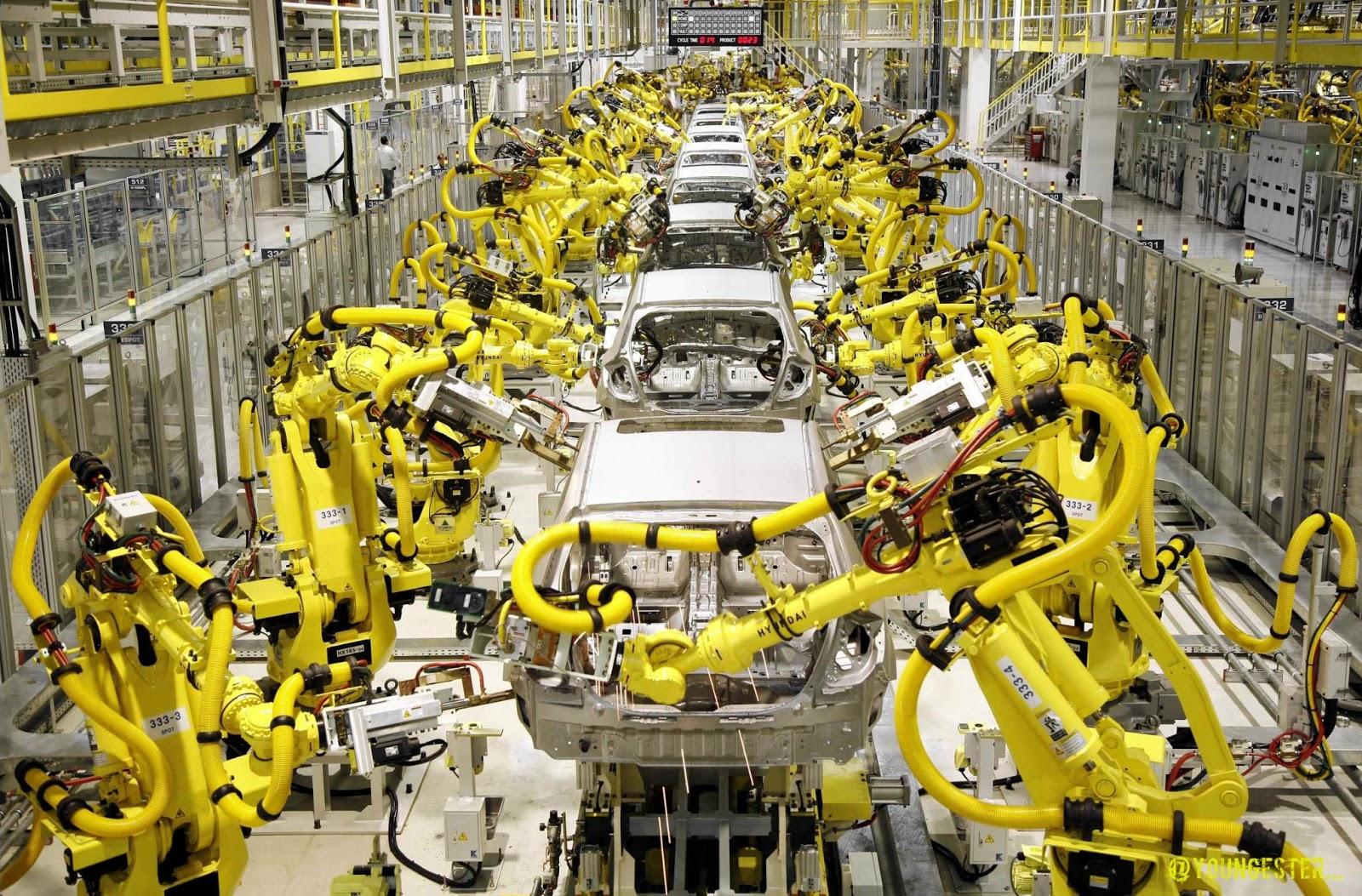

Mechanical Engineering is the discipline that applies the principles of engineering, physics, and materials science for the design, analysis, manufacturing, and maintenance of mechanical systems. It is the branch of engineering that involves the design, production, and operation of machinery. It is one of the oldest and broadest of the engineering disciplines.

Electromechanics combines processes and procedures drawn from electrical engineering and mechanical engineering. Electromechanics focuses on the interaction of electrical and mechanical systems as a whole and how the two systems interact with each other. This process is especially prominent in systems such as those of DC Machines which can be designed and operated to generate power from a mechanical process (generator) or used to power a mechanical effect (motor). Electrical engineering in this context also encompasses electronics engineering. Electromechanical devices are ones which have both electrical and mechanical processes. Strictly speaking, a manually operated switch is an electromechanical component due to the mechanical movement causing an electrical output. Though this is true, the term is usually understood to refer to devices which involve an electrical signal to create mechanical movement, or vice versa mechanical movement to create an electric signal. Often involving electromagnetic principles such as in relays, which allow a voltage or current to control another, usually isolated circuit voltage or current by mechanically switching sets of contacts, and solenoids, by which a voltage can actuate a moving linkage as in solenoid valves. Before the development of modern electronics, electromechanical devices were widely used in complicated subsystems of parts, including electric typewriters, teleprinters, clocks, initial television systems, and the very early electromechanical digital computers.

Civil Engineering - Infrastructure - Civil Engineering Body of Knowledge (wiki)

Geotechnical Engineering - Structural Engineering - Construction

Green Building - Stone Work - Wood Work

Environmental Engineering is the branch of engineering concerned with the application of scientific and engineering principles for protection of human populations from the effects of adverse environmental factors; protection of environments, both local and global, from potentially deleterious effects of natural and human activities; and improvement of environmental quality.

Aerospace Engineering (space travel) - Flying - Orbital Mechanics

Peter Palchinsky was a Russian engineer who played a significant role in the introduction of scientific management into Russian industry. (1875–22 May 1929). The Ghost of the Executed Engineer.

Chemical Engineering is a branch of engineering that applies physical sciences like physics and chemistry, as well as life sciences like microbiology and biochemistry, used all together with applied mathematics and economics to produce, transform, transport, and properly use chemicals, materials and energy. A chemical engineer designs large-scale processes that convert chemicals, raw materials, living cells, microorganisms and energy into useful forms and products.

Engineering Physics refers to the study of the combined disciplines of physics, mathematics and engineering, particularly computer, nuclear, electrical, electronic, materials or mechanical engineering. By focusing on the scientific method as a rigorous basis, it seeks ways to apply, design, and develop new solutions in engineering. Engineering physics or engineering science degrees are respected academic degrees awarded in many countries. It can be taught at the undergraduate level and is often designed as an honors program at some universities due to the rigorous nature of the academic curriculum which covers a wide spectrum of scientific disciplines.

Mechatronics is a multidisciplinary field of science that includes a combination of mechanical engineering, electronics, computer engineering, telecommunications engineering, systems engineering and control engineering. As technology advances, the subfields of engineering multiply and adapt. Mechatronics' aim is a design process that unifies these subfields. Originally, mechatronics just included the combination of mechanics and electronics, hence the word is a combination of mechanics and electronics; however, as technical systems have become more and more complex the definition has been broadened to include more technical areas.

Technologist is a specialist dedicated to the development, design, and implementation of engineering and technology. Engineering technology education is more of a broad specialized and applied engineering education.

Safe - Reliable - Sustainable

Industrial Engineering is a branch of engineering which deals with the optimization of complex processes, systems or organizations. Industrial engineers work to eliminate waste of time, money, materials, man-hours, machine time, energy and other resources that do not generate value.

Occupational Safety - Stress Testing - Form Follows Function - Sustainable - Design

Mechanism is a device designed to transform input forces and movement into a desired set of output forces and the movement. Mechanisms generally consist of moving components such as gears and gear trains, belt and chain drives, cam and follower mechanisms, and linkages as well as friction devices such as brakes and clutches, and structural components such as the frame, fasteners, bearings, springs, lubricants and seals, as well as a variety of specialized machine elements such as splines, pins and key.

Reliability Engineering is engineering that emphasizes dependability in the lifecycle management of a product. Dependability, or reliability, describes the ability of a system or component to function under stated conditions for a specified period of time. Reliability may also describe the ability to function at a specified moment or interval of time (Availability). Reliability engineering represents a sub-discipline within systems engineering. Reliability is theoretically defined as the probability of success.

Safety Engineering is an engineering discipline which assures that engineered systems provide acceptable levels of safety. It is strongly related to industrial engineering/systems engineering, and the subset system safety engineering. Safety engineering assures that a life-critical system behaves as needed, even when components fail. Earthquakes - Structural Engineering.

Quality Control - Risk Management - Scenarios - Codes - Capacity - Procedures

Security Engineering is a specialized field of engineering that focuses on the security aspects in the design of systems that need to be able to deal robustly with possible sources of disruption, ranging from natural disasters to malicious acts. It is similar to other systems engineering activities in that its primary motivation is to support the delivery of engineering solutions that satisfy pre-defined functional and user requirements, but it has the added dimension of preventing misuse and malicious behavior. Those constraints and restrictions are often asserted as a security policy.

Biosecurity is a set of preventive measures designed to reduce the risk of transmission of infectious diseases in crops and livestock, quarantined pests, invasive alien species, and living modified organisms. The emerging nature of biosecurity threats means that small scale risks blow up rapidly, thus an effective policy becomes a challenge for there are limitations on time and resources available for analysing threats and estimating the likelihood of their occurrence.

System Safety concept calls for a risk management strategy based on identification, analysis of hazards and application of remedial controls using a systems-based approach. This is different from traditional safety strategies which rely on control of conditions and causes of an accident based either on the Epidemiological analysis or as a result of investigation of individual past accidents. The concept of system safety is useful in demonstrating adequacy of technologies when difficulties are faced with probabilistic risk analysis. The underlying principle is one of synergy: a whole is more than sum of its parts. Systems-based approach to safety requires the application of scientific, technical and managerial skills to hazard identification, hazard analysis, and elimination, control, or management of hazards throughout the life-cycle of a system, program, project or an activity or a product. "Hazop" is one of several techniques available for identification of hazards.

Fail-Safe in engineering is a design feature or practice that in the event of a specific type of failure, inherently responds in a way that will cause no or minimal harm to other equipment, the environment or to people.

Inherent Safety has a low level of danger even if things go wrong. Inherent safety contrasts with other processes where a high degree of hazard is controlled by protective systems. As perfect safety cannot be achieved, common practice is to talk about inherently safer design. “An inherently safer design is one that avoids hazards instead of controlling them, particularly by reducing the amount of hazardous material and the number of hazardous operations in the plant.

Intrinsic Safety is a protection technique for safe operation of electrical equipment in hazardous areas by limiting the energy, electrical and thermal, available for ignition. In signal and control circuits that can operate with low currents and voltages, the intrinsic safety approach simplifies circuits and reduces installation cost over other protection methods. Areas with dangerous concentrations of flammable gases or dust are found in applications such as petrochemical refineries and mines. As a discipline, it is an application of inherent safety in instrumentation. High-power circuits such as electric motors or lighting cannot use intrinsic safety methods for protection.

Engineering Controls are strategies designed to protect workers from hazardous conditions by placing a barrier between the worker and the hazard or by removing a hazardous substance through air ventilation. Engineering controls involve a physical change to the workplace itself, rather than relying on workers' behavior or requiring workers to wear protective clothing. Engineering controls is the third of five members of the hierarchy of hazard controls, which orders control strategies by their feasibility and effectiveness. Engineering controls are preferred over administrative controls and personal protective equipment (PPE) because they are designed to remove the hazard at the source, before it comes in contact with the worker. Well-designed engineering controls can be highly effective in protecting workers and will typically be independent of worker interactions to provide this high level of protection. The initial cost of engineering controls can be higher than the cost of administrative controls or PPE, but over the longer term, operating costs are frequently lower, and in some instances, can provide a cost savings in other areas of the process. Elimination and substitution are usually considered to be separate levels of hazard controls, but in some schemes they are categorized as types of engineering control. The U.S. National Institute for Occupational Safety and Health researches engineering control technologies, and provides information on their details and effectiveness in the NIOSH Engineering Controls Database.

Hierarchy of Hazard Controls is a system used in industry to minimize or eliminate exposure to hazards. The hazard controls in the hierarchy are, in order of decreasing effectiveness: Hazard Elimination is a hazard control strategy based on completely removing a material or process causing a hazard. Hazard Substitution is a hazard control strategy in which a material or process is replaced with another that is less hazardous. Prevention through Design is the concept of applying methods to minimize occupational hazards early in the design process, with an emphasis on optimizing employee health and safety throughout the life cycle of materials and processes. It is a concept and movement that encourages construction or product designers to "design out" health and safety risks during design development. The concept supports the view that along with quality, programme and cost; safety is determined during the design stage. It increases the cost-effectiveness of enhancements to occupational safety and health. This method for reducing workplace safety risks lessens workers' reliance on personal protective equipment, which is the least effective of the hierarchy of hazard control. Administrative controls and Personal protective equipment.

Passive Nuclear Safety is a design approach for safety features, implemented in a Nuclear Reactor, that does not require any active intervention on the part of the operator or electrical/electronic feedback in order to bring the reactor to a safe shutdown state, in the event of a particular type of emergency (usually overheating resulting from a loss of coolant or loss of coolant flow). Such design features tend to rely more on the engineering of components such that their predicted behaviour would slow down, rather than accelerate, the deterioration of the reactor state; typically take advantages of natural forces or phenomena such as gravity, buoyancy, pressure differences, conduction or natural heat convection to accomplish safety functions without requiring an active power source. Many older common reactor designs use passive safety systems to a limited extent, rather, relying on active safety systems such as diesel powered motors. Some newer reactor designs feature more passive systems; the motivation being that they are highly reliable and reduce the cost associated with the installation and maintenance of systems that would otherwise require multiple trains of equipment and redundant safety class power supplies in order the achieve the same level of reliability. However, weak driving forces that power many passive safety features can pose significant challenges to effectiveness of a passive system, particularly in the short term following an accident.

Subsurface Utility Engineering refers to a branch of engineering that involves managing certain risks associated with utility mapping at appropriate quality levels, utility coordination, utility relocation design and coordination, utility condition assessment, communication of utility data to concerned parties, utility relocation cost estimates, implementation of utility accommodation policies, and utility design.

10 Biggest Architecture Fails In The World (youtube)

10 Embarrassing Architectural Failures (youtube)

10 Biggest Architectural Fails (youtube)

How Drilling a 14 in. Hole Created a 1.3K ft Deep Saltwater Lake Out of a 10 ft Deep Freshwater One (youtube) - Lake Peigneur is located in Louisiana near the Gulf of Mexico. Before 1980, it was an approximately 10-foot deep fresh water lake with an island in the middle. Next to it, and partially under it, Diamond Crystal Salt Company maintained a salt mine, with salt being mined near the lake since 1919.

Teaching Engineering

Teach Engineering - Try Engineering

Practical Engineering - Grady Hill House (youtube channel)

The Efficient Engineer (youtube channel)

Real Engineering (youtube channel)

Steve Mould (youtube channel)

Institute of Electrical and Electronics Engineers

National Academy of Engineering

Teenage Engineering

The American Society of Mechanical Engineers

Pritzker Architecture Prize

Arch 2o

Element 14 online community specifically for engineers.

Center for Advanced Engineering

Math Skills needed to become an Engineer

How much you use these skills will depend on the type of engineering work that you will be doing. Reading, writing, communication and problem solving will always be your most used skills in every profession. In order to find an engineering position that you like, you may have to move to another state or country. Scientist.

Math Skills needed to become an Engineer - Engineering Principles - Principles and Practice of Engineering Exam - PE Exam - Fundamentals of Engineering Exam.

Basic Arithmetic: All math is based on the idea that 1 plus 1 equals 2, and 1 minus 1 equals 0. Multiplication and division --2 times 2 and 4 divided by 2 -- are variations used to avoid multiple iterations of either subtraction or addition. One example of an engineer's use of basic arithmetic is the civil engineer's calculations for describing water flow across an open basin. The flow is reckoned in cubic feet per second, or Q, where Q equals the runoff coefficient times the intensity of the rain for a specified period, times the area of the basin. If the runoff coefficient is 2, the intensity, in inches of rain, is 4 and the basin -- a specified area of land -- is 1/2 acre, the engineer's formula resembles this: (2x4)/(.5x43,560), or 8/21,780. The result, 0.0003673, is the volume of water, in cubic feet per second, flowing across the land. - Math Knowledge - Next Generation Science Standards.

Algebra and Geometry: When several of the factors of a problem are known and one or more are unknown, engineers use Algebra, including differential equations in cases when there are several unknowns. Because engineers work to arrive at a solution to a physical problem, Geometry -- with its planes, circles and angles -- determines such diverse things as the torque used to turn a wheel, and reduces the design of a roadway's curve to an accurate engineering or construction drawing.

Trigonometry: Trigonometry is the science of measuring triangles. Engineers may use plane trigonometry to determine the size of an irregularly shaped parcel of land. It may also be used or to determine the height of an object based solely on the distance to the object and the angle, up or down, from the observer. Spherical trigonometry is used by naval engineers in ship design and by mechanical engineers working on such arcane projects as the design of mechanical hand for an underwater robot.

Statistics: By statistical analysis of the design, the engineer can tell what percentage of a design will need armor or reinforcement or where any likely failures will occur. For the civil engineer, statistics appear as the concentration of rainfall, wind loads and bridge design. In many locations, engineers designing drainage systems must design for a 50- or 100-year storm in their calculations, a significant change from the normal rain concentration.

Calculus: Calculus is used by engineers to determine rates of change or rates by which factors, such as acceleration or weight, change. It might tell NASA scientists at what point the change in a satellite's orbit will cause the satellite to strike an object in space. A more mundane task for calculus might be determining how large a box must be to accommodate a specific number of things. An engineer who designs packaging, for example, might know that a product of a certain weight must be packaged in groups of no more than 10 because of their weight. Using calculus, he can calculate both the optimum number of objects per box, plus the optimum size of the box.

Architecture

Architecture is both the process and the product of

planning,

designing, and constructing buildings and other physical

structures. Architectural works, in the material form of buildings, are

often perceived as cultural symbols and as works of art. Historical

civilizations are often identified with their surviving architectural

achievements. Architecture" can mean: A general term to describe buildings

and other physical structures. The art and science of designing buildings

and (some) nonbuilding structures. The style of design and method of

construction of buildings and other physical structures. Knowledge of art,

science, technology, and humanity. The practice of the architect, where

architecture means offering or rendering professional services in

connection with the design and construction of buildings, or built

environments. The design activity of the architect, from the macro-level

(urban design, landscape architecture) to the micro-level (construction

details and furniture).

Building Analyst.

Architecture is both the process and the product of

planning,

designing, and constructing buildings and other physical

structures. Architectural works, in the material form of buildings, are

often perceived as cultural symbols and as works of art. Historical

civilizations are often identified with their surviving architectural

achievements. Architecture" can mean: A general term to describe buildings

and other physical structures. The art and science of designing buildings

and (some) nonbuilding structures. The style of design and method of

construction of buildings and other physical structures. Knowledge of art,

science, technology, and humanity. The practice of the architect, where

architecture means offering or rendering professional services in

connection with the design and construction of buildings, or built

environments. The design activity of the architect, from the macro-level

(urban design, landscape architecture) to the micro-level (construction

details and furniture).

Building Analyst.Architectural Engineering is the application of engineering principles and technology to building design and construction. Definitions of an architectural engineer may refer to: An engineer in the structural, mechanical, electrical, construction or other engineering fields of building design and construction. A licensed engineering professional in parts of the United States. Architectural engineers are those who work with other engineers and architects for the designing and construction of buildings. Glossary of Architecture (wiki).

Architecture Articulation is a method of styling the joints in the formal elements of architectural design. Through degrees of articulation, each part is united with the whole work by means of a joint in such a way that the joined parts are put together in styles ranging from exceptionally distinct jointing to the opposite of high articulation—fluidity and continuity of joining. In highly articulated works, each part is defined precisely and stands out clearly. The articulation of a building reveals how the parts fit into the whole by emphasizing each part separately.

Modern Architecture uses advanced technology construction and modern building materials. Taller, lighter and stronger.

Contemporary Architecture - Great Images of Buildings.

Biomimetic Architecture is a contemporary philosophy of architecture that seeks solutions for sustainability in nature, not by replicating the natural forms, but by understanding the rules governing those forms. It is a multi-disciplinary approach to sustainable design that follows a set of principles rather than stylistic codes. It is part of a larger movement known as biomimicry, which is the examination of nature, its models, systems, and processes for the purpose of gaining inspiration in order to solve man-made problems.

Architectural Standards - Framing - Structural Engineering

Architectural Theory is the act of thinking, discussing, and writing about architecture. Architectural theory is taught in most architecture schools and is practiced by the world's leading architects.

Outline of Architecture (PDF)

Brutalist Architecture is characterized by simple, block-like structures that often feature bare building materials. Exposed concrete is favored in construction; however, some examples are primarily made of brick. Curbed Hands-On Architecture Explainer Brutalism (youtube).

Architectural Lighting Design is a field within architecture, interior design and electrical engineering that is concerned with the design of lighting systems, including natural light, electric light, or both, to serve human needs. The design process takes account of: The kind of human activity for which lighting is to be provided. The amount of light required. The color of the light as it may affect the views of particular objects and the environment as a whole. The distribution of light within the space to be lighted, whether indoor or outdoor. The effect of the lightened system itself on the user. The objective of lighting design is the human response, to see clearly and without discomfort. The objective of architectural lighting design is to further the design of architecture or the experience of buildings and other physical structures. Light Meters or Light Detectors are also used in illumination. Their purpose is to measure the illumination level in the interior and to switch off or reduce the output level of luminaires. This can greatly reduce the energy burden of the building by significantly increasing the efficiency of its lighting system. It is therefore recommended to use light meters in lighting systems, especially in rooms where one cannot expect users to pay attention to manually switching off the lights. Examples include hallways, stairs, and big halls. Facing the Sun.

Function - Form

Proportion Architecture is a central principle of architectural theory and an important connection between mathematics and art. It is the visual effect of the relationships of the various objects and spaces that make up a structure to one another and to the whole. These relationships are often governed by multiples of a standard unit of length known as a "module".

Form Follows Function is the principle of design that the shape of a building or object should be primarily based upon its intended Function or Purpose. The principle is associated with modernist architecture and industrial design in the 20th century. Safety.

Functionalism in architecture is the principle that buildings should be designed based solely on the purpose and function of the building. This principle is less self-evident than it first appears, and is a matter of confusion and controversy within the profession, particularly in regard to modern architecture.

Green Building - Working Together - Human Body

Functional Design is a paradigm used to simplify the design of hardware and software devices such as computer software and increasingly, 3D Models. A functional design assures that each modular part of a device has only one responsibility and performs that responsibility with the minimum of side effects on other parts. Functionally designed modules tend to have low coupling.

Structure Follows Strategy is a business principle that states that the divisions, departments, teams, processes and technology of an organization are designed to achieve a firm's strategy.

Aesthetics (Feng Shui) - Building Design Guidelines - Obsolescence

Loose Coupling system is one in which each of its components has, or makes use of, little or no knowledge of the definitions of other separate components. Subareas include the coupling of classes, interfaces, data, and services. Loose coupling is the opposite of tight coupling. Multi-Use.

Coupling in computer programming is the degree of interdependence between software modules; a measure of how closely connected two routines or modules are; the strength of the relationships between modules. Coupling is usually contrasted with cohesion. Low coupling often correlates with high cohesion, and vice versa. Low coupling is often a sign of a well-structured computer system and a good design, and when combined with high cohesion, supports the general goals of high readability and maintainability

Cohesion in computer science refers to the degree to which the elements inside a module belong together. In one sense, it is a measure of the strength of relationship between the methods and data of a class and some unifying purpose or concept served by that class. In another sense, it is a measure of the strength of relationship between the class’s methods and data themselves. Cohesion is an ordinal type of measurement and is usually described as “high cohesion” or “low cohesion”. Modules with high cohesion tend to be preferable, because high cohesion is associated with several desirable traits of software including robustness, reliability, reusability, and understandability. In contrast, low cohesion is associated with undesirable traits such as being difficult to maintain, test, reuse, or even understand. Cohesion is often contrasted with coupling, a different concept. High cohesion often correlates with loose coupling, and vice versa.

Function in engineering is interpreted as a specific process, action or task that a system is able to perform. Requirements usually specifies the most important attributes of the requested system. In the Design specification documents, physical or software processes and systems are frequently the requested functions.

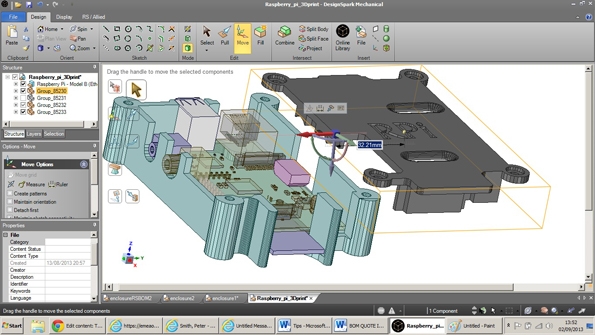

Models - 3D Models - Drawings

Design - Location of Building

Building Commissioning is the process of verifying, in new construction, all (or some, depending on scope) of the subsystems for mechanical (HVAC), plumbing, electrical, fire/life safety, building envelopes, interior systems (example laboratory units), co-generation, utility plants, sustainable systems, lighting, wastewater, controls, and building security to achieve the owner's project requirements as intended by the building owner and as designed by the building architects and engineers. Recommissioning is the methodical process of testing and adjusting the aforementioned systems in existing buildings.

General Contractors

Cybernetics is a transdisciplinary approach for exploring regulatory systems—their structures, constraints, and possibilities.

Energy - Management

City Planning - Green Building - Hakerspace

Architecture-Engineering-Construction (ACE) - ACE Mentor

Engineering Process Outsourcing for the architecture, engineering and construction (AEC) industry is a resource for the industries of the built environment. The EPO industry supports architecture, engineering and construction industries worldwide.

Architecture and Vision

Passivity Engineering is a property of engineering systems, used in a variety of engineering disciplines, but most commonly found in analog electronics and control systems. A passive component, depending on field, may be either a component that consumes (but does not produce) energy (thermodynamic passivity), or a component that is incapable of power gain (incremental passivity).

Why do most Church Facades have 3 door design with 1 big door in center with 2 small doors on either side of the big door?

Triptych is a work of art (usually a panel painting) that is divided into three sections, or three carved panels that are hinged together and can be folded shut or displayed open. Arches.

Architecture of Cathedrals and Great Churches (wiki) - Romanesque Architecture (wiki)

Facade is generally one exterior side of a building, usually the front. Facadism refers to an architectural and construction practice where the facade of a building was designed or constructed separately from the rest of a building.

Vestibule or small foyer leading into a larger space, such as a lobby, entrance hall, passage, etc., for the purpose of waiting, withholding the larger space view, reducing heat loss, providing space for outwear, etc.

Pillar is a tall vertical structure of stone, wood, or metal, used as a support for a building, or as an ornament or monument.

Column or pillar in architecture and structural engineering is a structural element that transmits, through compression, the weight of the structure above to other structural elements below. In other words, a column is a compression member.

Pedestal or plinth is the support of a statue or a vase, and of a column in architecture. Smaller pedestals, especially if round in shape may be called socles.

Antoni Gaudí was a Spanish architect known as the greatest exponent of Catalan Modernism. Gaudí's works have a highly individualized, one-of-a-kind style. Most are located in Barcelona, including his main work, the church of the Sagrada Família. Gaudí's work was influenced by his passions in life: architecture, nature, and religion. He considered every detail of his creations and integrated into his architecture such crafts as ceramics, stained glass, wrought ironwork forging and carpentry. He also introduced new techniques in the treatment of materials, such as trencadís which used waste ceramic pieces. Under the influence of neo-Gothic art and Oriental techniques, Gaudí became part of the Modernista movement which was reaching its peak in the late 19th and early 20th centuries. His work transcended mainstream Modernisme, culminating in an organic style inspired by natural forms. Gaudí rarely drew detailed plans of his works, instead preferring to create them as three-dimensional scale models and moulding the details as he conceived them. Gaudí's work enjoys global popularity and continuing admiration and study by architects. His masterpiece, the still-incomplete Sagrada Família, is the most-visited monument in Spain. Between 1984 and 2005, seven of his works were declared World Heritage Sites by UNESCO. Gaudí's Roman Catholic faith intensified during his life and religious images appear in many of his works. This earned him the nickname "God's Architect" and led to calls for his beatification. (June 25th 1852 – June 10th 1926 Barcelona, Catalonia, Spain). Stone Work.

American Institute of Architects

National Professional Association of Architects

Arch Kidecture

Baroque is a style of architecture, music, dance, painting, sculpture and other arts that flourished in Europe from the early 17th century until the 1740s. In the territories of the Spanish and Portuguese empires including the Iberian Peninsula it continued, together with new styles, until the first decade of the 1800s. It followed Renaissance art and Mannerism and preceded the Rococo (in the past often referred to as "late Baroque") and Neoclassical styles. It was encouraged by the Catholic Church as a means to counter the simplicity and austerity of Protestant architecture, art and music, though Lutheran Baroque art developed in parts of Europe as well. The Baroque style used contrast, movement, exuberant detail, deep colour, grandeur and surprise to achieve a sense of awe. The style began at the start of the 17th century in Rome, then spread rapidly to France, northern Italy, Spain and Portugal, then to Austria, southern Germany and Russia. By the 1730s, it had evolved into an even more flamboyant style, called rocaille or Rococo, which appeared in France and Central Europe until the mid to late 18th century. In the decorative arts there is an excess of ornamentation. The departure from Renaissance classicism has its own ways in each country. But a general feature is that everywhere the starting point is the ornamental elements introduced by the Renaissance. The classical repertoire is crowded, dense, overlapping, loaded, in order to provoke shock effects. New motifs introduced by Baroque are: the cartouche, trophies and weapons, baskets of fruit or flowers, and others, made in marquetry, stucco, or carved.

Bird Friendly Glass. Researchers estimate that hundreds of millions of birds are killed each year in North America due to collisions with glass on human-built structures, making bird collisions one of the most significant causes of avian mortality globally. It is the reflective and transparent characteristics of glass that create the danger for birds, as they cannot see it as a barrier. They fly to sky and trees reflected by or on the other side of a window or railing and collide fatally with the glass. To prevent these collisions, glass must somehow be made visible to birds. Birds are able to see light in the ultraviolet spectrum. So we created visual markers alerting birds to a barrier while keeping the aesthetic transparency of glass.

Building Codes - Rules for Building

Building Code is a set of rules that specify the Architectural Standards for constructed objects such as buildings and nonbuilding structures. The main purpose of building codes is to protect public health, safety and general welfare as they relate to the construction and occupancy of buildings and structures. The building code becomes law of a particular jurisdiction when formally enacted by the appropriate governmental or private authority. Regulations - Statute.

City Development - Surveying - Building Analyst - Earthquakes

Zoning describes the control by authority which designates legal areas in a municipality to permit and prohibit land uses. Zoning may specify a variety of outright and conditional uses of land. It may also indicate the size and dimensions of land area as well as the form and scale of buildings. These guidelines are set in order to guide urban growth and development.

Jay Austin's Beautiful, Illegal Tiny House (youtube) There are Cities that have no Zoning Rules.

International Code Council - Public Codes - Nuisance

Housing Types - Location - Orientation - Design Guides

Construction Permit refers to the approval needed for construction or expansion (including significant renovation) in some jurisdictions.

Fire Safety (PDF) - Fire Code (PDF) - Safety Engineering

Planning and Zoning Commission is a local elected or appointed government board charged with recommending to the local town or city council the boundaries of the various original zoning district and appropriate regulations to be enforced therein and any proposed amendments thereto and shall collect data and keep itself informed as to the best practices generally in effect in the matter city planning and zoning to the end that it may be qualified to act on measures affecting the present and future movement of traffic, the segregation of residential and business districts and the convenience and safety of persons and property in any way dependent on city planning and zoning. Some jurisdictions may refer to them also planning commissions, planning boards, zoning commissions, and zoning boards. The chairman of the Planning and Zoning Commission (or a staff member) is responsible for publishing public hearing in the newspaper about certain matters that come before the commission. Most municipal or county Planning and Zoning Commissions consist of five to seven members. This number does not include alternates. In some states, planning and zoning commissions are regional or county. Some communities elect planning and zoning commission members. In other jurisdictions, the Planning and Zoning Commissioners are appointed by the Mayor or First Selectman of the city or town and approved by the city's legislative body, i.e. city council, board of aldermen, etc. (some planning commissioners are appointed by the City Commission as a whole). Please note that planning and zoning commissions may also be approving agencies for development permits, variances to the zoning code. Other jurisdictions may have separate zoning board of adjustments or appeals appointed by the governing body that perform the function instead of the planning and zoning commission doing it. Some jurisdictions have featured court appointed zoning boards/boards of adjustment and appeals due to the quasi-judicial functions. Town Ordinance.

Change Order refers to the changes in the scope of work agreed to by the owner, contractor, and architect or engineer. A change order is work that is added to or deleted from the original scope of work of a contract, however, depending on the magnitude of the change, it may or may not alter the original contract amount and/or completion date. A change order may force a new project to handle significant changes to the current project. Change Request (wiki). Warning: some contractors use change requests to charge the customer more money over the original price that was bid. So the lowest bid might not be the price you pay. Construction Fraud.

Contractor is a person or company that undertakes a contract to provide materials or labor to perform a service or do a job.

Subcontractor is an individual or in many cases a business that signs a contract to perform part or all of the obligations of another's contract.

Accessory use and an accessory structure typical accessory use to a residence, like a swimming pool or a tennis court.

Home Inspection is a limited, non-invasive examination of the condition of a home, often in connection with the sale of that home. Home inspections are usually conducted by a home inspector who has the training and certifications to perform such inspections. The inspector prepares and delivers to the client a written report of findings. The client then uses the knowledge gained to make informed decisions about their pending real estate purchase. The home inspector describes the condition of the home at the time of inspection but does not guarantee future condition, efficiency, or life expectancy of systems or components. International Association of Certified Home Inspectors.

Private Certifications and inspections are only as good as the people doing the inspections, and only if they are following and conforming to high quality standards, and that the inspection proves that there's no substandard materials or substandard craftsmanship. Corrupt developers love to cut corners and use low quality products just so they make more money at other peoples expense. They love to farm out to subcontractors who are unaware of the defects. When criminal developers don't follow building standards and exploit weak or relax regulations and use non-conforming standards or non-compliance building methods, then homeowners suffer the consequences and become victimized by greedy and narrow minded developers.

Structural Engineering - Electrical Work (electricity)

Building Performance of a building or built environment is the efficiency of functioning of buildings and the construction industry, its impact on natural environment, urban environment and its users. It is achieved through means such as architectural design values, building science, architectural engineering, efficient energy use and sustainability.

Sim Scale Simulation Software and Design Validation.

Southeastern Consulting Engineers, Inc. provides professional engineering services in whatever capacity best fits our client's needs. Professionalism in all facets of civil and structural engineering including commercial and residential structural engineering, site planning, land use planning, utility engineering, construction engineering inspection, FDEP permitting, subdivision planning and design, and more. Our team of professionals currently provide our services to clients in Florida but are capable within the entire southeast.

Energy Monitoring - Indoor Air

Recreational Vehicle Industry Association certifies Tiny Homes to make sure they're up to recreational vehicle building codes and are safe for habitation.

Plumbing is any system that conveys fluids for a wide range of applications. Plumbing uses pipes, valves, plumbing fixtures, tanks, and other apparatuses to convey fluids. Heating and cooling (HVAC), Waste Water Removal, and potable water delivery are among the most common uses for plumbing, but it is not limited to these applications. In the developed world, plumbing infrastructure is critical to public health and sanitation. Boilermakers and pipefitters are not plumbers, although they work with piping as part of their trade, but their work can include some plumbing.

Building Sciences

Building Science is the collection of scientific knowledge and experience that focuses on the analysis and control of the physical phenomena affecting buildings and architecture. It traditionally includes areas such as building materials, building envelope, heating, ventilation and air conditioning systems, natural and electrical lighting, acoustic, indoor air quality, passive strategies, fire protection, and renewable energies in buildings.

Transformation Design is a human-centered, interdisciplinary process that seeks to create desirable and sustainable changes in behavior and form – of individuals, systems and organizations – often for socially progressive ends.

Human Factors Ergonomics, comfort design, functional design, and systems, is the practice of designing products, systems, or processes to take proper account of the interaction between them and the people who use them. Posture - Safety Engineering.

Air Flow Control in Buildings - Effect of High-Rise open ground floor to wind flow and Natural Ventilation.

Air Rights are the property interest in the "space" above the earth's surface. Generally speaking, owning, or renting, land or a building includes the right to use and develop the space above the land without interference by others.

Constructions

Construction is the process of constructing a building or infrastructure. There are three sectors of construction: buildings, infrastructure and industrial. Building construction is usually further divided into residential and non-residential. Infrastructure, also called heavy civil or heavy engineering, includes large public works, dams, bridges, highways, railways, water or wastewater and utility distribution. Industrial construction includes offshore construction (mainly of energy installations), mining and quarrying, refineries, chemical processing, power generation, mills and manufacturing plants.

Constructing is to make something by combining materials and parts. To put together something out of artificial or natural components or parts. Create by organizing and linking ideas, arguments, constructs or concepts. Manufacturing.

Construction Worker is a manual laborer employed in the physical construction of the built environment and its infrastructure. Labourers carry out a wide range of practical tasks to help tradespersons on construction sites. Labourers clean the construction site on a regular basis. They use tools such as rakes, shovels, and wheelbarrows to remove rubble, scraps of metal, and wood or they might also need to sweep out certain areas, and get building supplies in order. Construction workers may also colloquially be referred to as "hard hat workers" or "hard hats", as they often wear hardhats for safety.

Build is to make by combining materials and parts. Give form to something according to a plan. Form or accumulate steadily. Develop and grow. Bolster or strengthen. To create something abstract.

Building is the act of constructing something. The commercial activity involved in repairing old structures or constructing new ones. Building is a structure with a roof and walls standing more or less permanently in one place on a foundation, such as a house or factory. Models.

Make is to give certain properties to something. To be engaged in an activity that causes something to be or to become. To give rise to something or cause something to happen or to occur. Appear to begin an activity. Proceed along a path. To create, design or manufacture a man-made product. Be or be capable of being changed or made into. Make by shaping or bringing together constituents or by combining materials and parts. Change from one form into another. Achieve a point or goal. Perform or carry out. Undergo fabrication or creation. Calculate as being. Favor the development of. To formulate, or derive in the mind. Behave in a certain way.

Built Environment refers to the human-made environment that provides the setting for human activity, ranging in scale from buildings to cities and beyond. It has been defined as "the human-made space in which people live, work and recreate on a day-to-day basis." The built environment encompasses places and spaces created or modified by people to serve their needs of accommodation, organisation and representation. The sciences of the built environment cover architecture, urbanism, building technology, civil engineering, landscaping and the management of built stock mutations and operations. In recent years, public health research has expanded the definition of "built environment" to include healthy food access, community gardens, mental health, physical health,"walkability", and "bikeability".

Building Material is any material which is used for construction purposes. Many naturally occurring substances, such as clay, rocks, sand, and wood, even twigs and leaves, have been used to construct buildings. Apart from naturally occurring materials, many man-made products are in use, some more and some less synthetic. The manufacturing of building materials is an established industry in many countries and the use of these materials is typically segmented into specific specialty trades, such as carpentry, insulation, plumbing, and roofing work. They provide the make-up of habitats and structures including homes.

Scaffolding - Framing - Wood Work - Playground

Makeshift is something serving as a temporary substitute and sufficient for the time being.

Foundations

Foundation is the element of an architectural structure which connects it to the ground, and transfers loads from the structure to the ground. Foundations are generally considered either shallow or deep. Foundation engineering is the application of soil mechanics and rock mechanics and Geotechnical Engineering in the design of foundation elements of structures.

Knowledge Foundation

Concrete - Cement - Stone Work - Earthquakes - Metal Working

Bridges

Bridge is a structure built to span physical obstacles without closing the way underneath such as a body of water, valley, or road, for the purpose of providing passage over the obstacle, usually something that can be detrimental to cross otherwise. There are many different designs that each serve a particular purpose and apply to different situations. Designs of bridges vary depending on the function of the bridge, the nature of the terrain where the bridge is constructed and anchored, the material used to make it, and the funds available to build it. Geotechnical Engineering.

Suspension Bridge is a type of bridge in which the deck (the load-bearing portion) is hung below suspension cables on vertical suspenders. The first modern examples of this type of bridge were built in the early 1800s. Simple Suspension Bridges, which lack vertical suspenders, have a long history in many mountainous parts of the world. This type of bridge has cables suspended between towers, plus vertical suspender cables that carry the weight of the deck below, upon which traffic crosses. This arrangement allows the deck to be level or to arc upward for additional clearance. Like other suspension bridge types, this type often is constructed without falsework. The suspension cables must be anchored at each end of the bridge, since any load applied to the bridge is transformed into a tension in these main cables. The main cables continue beyond the pillars to deck-level supports, and further continue to connections with anchors in the ground. The roadway is supported by vertical suspender cables or rods, called hangers. In some circumstances, the towers may sit on a bluff or canyon edge where the road may proceed directly to the main span, otherwise the bridge will usually have two smaller spans, running between either pair of pillars and the highway, which may be supported by suspender cables or may use a truss bridge to make this connection. In the latter case there will be very little arc in the outboard main cables. Tacoma Narrows Bridge (1940) (wiki).

Truss is an assembly of beams or other elements that creates a rigid structure. In engineering, a truss is a structure that "consists of two-force members only, where the members are organized so that the assemblage as a whole behaves as a single object". A "two-force member" is a structural component where force is applied to only two points. Although this rigorous definition allows the members to have any shape connected in any stable configuration, trusses typically comprise five or more triangular units constructed with straight members whose ends are connected at joints referred to as nodes. In this typical context, external forces and reactions to those forces are considered to act only at the nodes and result in forces in the members that are either tensile or compressive. For straight members, moments (torques) are explicitly excluded because, and only because, all the joints in a truss are treated as revolutes, as is necessary for the links to be two-force members. A planar truss is one where all members and nodes lie within a two-dimensional plane, while a space truss has members and nodes that extend into three dimensions. The top beams in a truss are called top chords and are typically in compression, the bottom beams are called bottom chords, and are typically in tension. The interior beams are called webs, and the areas inside the webs are called panels, or from graphic statics (see Cremona diagram) polygons.

Tensegrity is a structural principle based on a system of isolated components under compression inside a network of continuous tension, and arranged in such a way that the compressed members (usually bars or struts) do not touch each other while the prestressed tensioned members (usually cables or tendons) delineate the system spatially.

Rio-Antirrion Bridge is one of the world's longest multi-span cable-stayed bridges and longest of the fully suspended type. It crosses the Gulf of Corinth near Patras, linking the town of Rio on the Peloponnese peninsula to Antirrio on mainland Greece by road. It opened one day before the Athens 2004 Summer Olympics, on 12 August 2004, and was used to transport the Olympic Flame.

Footbridge is a bridge designed for pedestrians and in some cases cyclists, animal traffic, and horse riders, instead of vehicular traffic. Footbridges complement the landscape and can be used decoratively to visually link two distinct areas or to signal a transaction. In many developed countries, footbridges are both functional and can be beautiful works of art and sculpture.

Leonardo da Vinci's Self Supporting Bridge - How to Build Your Own (youtube) - Vebjørn Sand Da Vinci Project is a laminated-wood parabolic-arch pedestrian bridge in Norway.

Which is the Strongest Bridge? Hydraulic Press Test!(youtube)

The Unfoldable Bridge Construction - Die Brücke zum Aufklappen (youtube)

How are Underwater Structures Built? (youtube)

Caisson is a watertight retaining structure used, for example, to work on the foundations of a bridge pier, for the construction of a concrete dam, or for the repair of ships. Caissons are constructed in such a way that the water can be pumped out, keeping the work environment dry. When piers are being built using an open caisson, and it is not practical to reach suitable soil, friction pilings may be driven to form a suitable sub-foundation. These piles are connected by a foundation pad upon which the column pier is erected. Underwater Construction Corporation.

Tremie is a watertight pipe, usually of about 250mm inside diameter (150 to 300 mm), with a conical hopper at its upper end above the water level. It may have a loose plug or a valve at the bottom end. A tremie is used to pour concrete underwater in a way that avoids washout of cement from the mix due to turbulent water contact with the concrete while it is flowing. This produces a more reliable strength of the product. Common applications include the following. Caissons, which are the foundations of bridges, among other things, that span bodies of water. Pilings. Monitoring wells. Builders use tremie methods for materials other than concrete, and for industries other than construction. For example, bentonite slurries for monitoring wells are often emplaced via tremie pipe. Hole Drilling.

Dewatering is the removal of water from solid material or soil by wet classification, centrifugation, filtration, or similar solid-liquid separation processes, such as removal of residual liquid from a filter cake by a filter press as part of various industrial processes. Construction dewatering, unwatering, or water control are common terms used to describe removal or draining groundwater or surface water from a riverbed, construction site, caisson, or mine shaft, by pumping or evaporation. On a construction site, this dewatering may be implemented before subsurface excavation for foundations, shoring, or cellar space to lower the water table. This frequently involves the use of submersible "dewatering" pumps, centrifugal ("trash") pumps, eductors, or application of vacuum to well points.

Cofferdam is an enclosure built within, or in pairs across, a body of water to allow the enclosed area to be pumped out. This pumping creates a dry work environment for the work to be carried out. Enclosed coffers are commonly used for construction or repair of permanent dams, oil platforms, bridge piers, et cetera, built within or over water. These cofferdams are usually welded steel structures, with components consisting of sheet piles, wales, and cross braces. Such structures are usually dismantled after the construction work is completed.

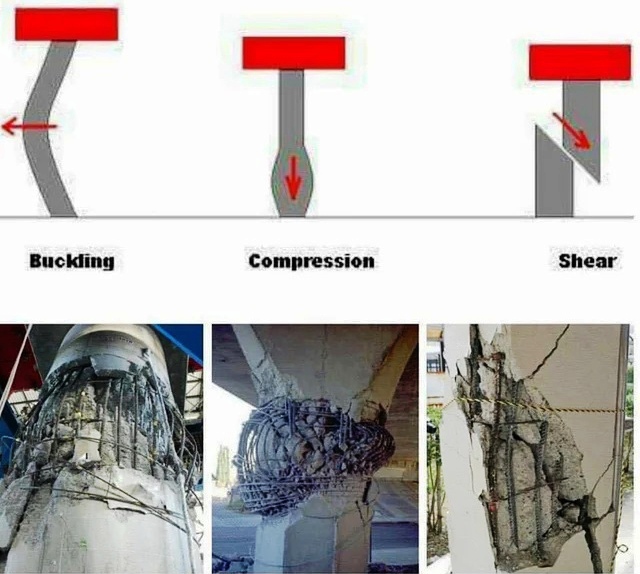

Earthquake Resistant Construction

Earthquake Resistant Structures are structures designed to

withstand earthquakes. While no structure can be entirely immune to damage

from earthquakes, the goal of earthquake-resistant construction is to

erect structures that fare better during seismic activity than their

conventional counterparts.

Earthquake Resistant Structures are structures designed to

withstand earthquakes. While no structure can be entirely immune to damage

from earthquakes, the goal of earthquake-resistant construction is to

erect structures that fare better during seismic activity than their

conventional counterparts.Strength of Materials - Safety Engineering - Center of Gravity

Build an Earthquake Proof Building

Earthquake News

Earthquake Engineering Research Center

Earthquake Resistant Building

World's Largest Earthquake Test (youtube)

Energy Absorbing Structure

NS Honeycombs Demonstration (youtube)

Tech 21

Building to withstand Disasters pays off big, study shows

Seismic Isolation Floor Systems. There are two types, including the base-isolated foundations SKID for two dimensions and the base-isolated foundations KEEP for two / three dimensions. They can be installed into both new and existing buildings.

Server room with seismic isolation floor in East Japan Great Earthquake disaster (youtube)

Seismic Retrofit is the modification of existing structures to make them more resistant to seismic activity, ground motion, or soil failure due to earthquakes. Earthquake Retrofitting.

Seismic Analysis is a subset of structural analysis and is the calculation of the response of a building (or nonbuilding) structure to earthquakes. It is part of the process of structural design, earthquake engineering or structural assessment and retrofit (see structural engineering) in regions where earthquakes are prevalent.

Flexible is the property of being flexible and easy to bend or easily shaped. The quality of being adaptable or variable.

Flexibility in Engineering (repurpose) - Structural Analysis

Mechanical Impedance is a measure of how much a structure resists motion when subjected to a harmonic force. It relates forces with velocities acting on a mechanical system. The mechanical impedance of a point on a structure is the ratio of the force applied at a point to the resulting velocity at that point.

Compliant Mechanism are flexible mechanisms that transfer an input force and displacement at one port to an output force and displacement at another port through elastic body deformation. These may be monolithic (single-piece) or jointless structures. Since many compliant mechanisms are single-piece structures, there is no need of assembly. With no joints, "rubbing" between two parts or friction as seen at the joints of rigid body mechanisms is absent. Compliant mechanisms are elastic.

Displacement is the moving of something from its place or position. The action of uniform movement without rotation. Cause to move or shift into a new position or place, both in a concrete and in an abstract sense. Deformation.

Displacement vector is a vector whose length is the shortest distance from the initial to the final position of a point P. It quantifies both the distance and direction of an imaginary motion along a straight line from the initial position to the final position of the point. A displacement may be identified with the translation that maps the initial position to the final position. A displacement may be also described as a 'relative position', that is, as the final position xf of a point relatively to its initial position xi. The corresponding displacement vector can be defined as the difference between the final and initial positions.

Simple Harmonic Motion is a special type of periodic motion or oscillation motion where the restoring force is directly proportional to the displacement and acts in the direction opposite to that of displacement.

Building Resonance: Structural stability during earthquakes. All buildings have a natural period, or resonance, which is the number of seconds it takes for the building to naturally vibrate back and forth. Structural Engineering.

Control of Floor Vibration. Excessive floor vibration has become a greater problem as new rhythmic activities, such as aerobics, and long-span floor structures have become more common.

Anti-Vibration Pads or vibration isolators, are used in a variety of applications, such as to reduce the transmitted vibration from a washing machine to the surrounding area. ... Foam, neoprene, and rubber vibration isolation pads are commonly used with appliances such as washing machines.

Pile Rafts are structural foundation systems that derive their strength from the combined pile and base soil resistance. The term “raft” in pile rafts, refers to the fact that the combined foundation is “floating” in soil.

End Bearing Piles are the bottom end of the pile rests on a layer of especially strong soil or rock. The load of the building is transferred through the pile onto the strong layer. In a sense, this pile acts like a column.

Rod End Bearing also known as a heim joint (N. America) or rose joint (U.K. and elsewhere), is a mechanical articulating joint. Such joints are used on the ends of control rods, steering links, tie rods, or anywhere a precision articulating joint is required, and where a clevis end (which requires perfect 90 degree alignment between the attached shaft and the second component) is unsuitable. A ball swivel with an opening through which a bolt or other attaching hardware may pass is pressed into a circular casing with a threaded shaft attached. The threaded portion may be either male or female. The heim joint's advantage is that the ball insert permits the rod or bolt passing through it to be misaligned to a limited degree (an angle other than 90 degrees). A link terminated in two heim joints permits misalignment of their attached shafts (viz., other than 180 degrees).

Girder is a support beam used in construction. It is the main horizontal support of a structure which supports smaller beams.

Deflection is the degree to which a structural element is displaced under a load. It may refer to an angle or a distance.

Tuned Mass Damper is a device mounted in structures to reduce the amplitude of mechanical vibrations. Their application can prevent discomfort, damage, or outright structural failure. They are frequently used in power transmission, automobiles, and buildings.

Twist Building Design - Time-Frequency Analysis of Postural Sway (sway Frequency)

Shear Wall is a vertical element of a seismic force resisting system that is designed to resist in-plane lateral forces, typically wind and seismic loads. In many jurisdictions, the International Building Code and International Residential Code govern the design of shear walls. A shear wall resists loads parallel to the plane of the wall. Collectors, also known as drag members, transfer the diaphragm shear to shear walls and other vertical elements of the seismic force resisting system. Shear walls are typically light-framed or braced wooden walls with shear panels, reinforced concrete walls, reinforced masonry walls, or steel plates. Plywood is the conventional material used in wood (timber) shear walls, but with advances in technology and modern building methods, other prefabricated options have made it possible to inject shear assemblies into narrow walls that fall at either side of an opening. Sheet steel and steel-backed shear panels in the place of structural plywood in shear walls has proved to provide stronger seismic resistance.

Designing a flexible material to protect buildings, military personnel. A team of engineers has designed a flexible material that can help buildings withstand multiple waves of energy traveling through a solid material, including the simultaneous forward and backward and side-to-side motions found in earthquakes.

Vortex Shedding is an oscillating flow that takes place when a fluid such as air or water flows past a bluff (as opposed to streamlined) body at certain velocities, depending on the size and shape of the body. In this flow, vortices are created at the back of the body and detach periodically from either side of the body. See Von Kármán vortex street. The fluid flow past the object creates alternating low-pressure vortices on the downstream side of the object. The object will tend to move toward the low-pressure zone. (Rounded Edges - Round Corners). If the bluff structure is not mounted rigidly and the frequency of vortex shedding matches the resonance frequency of the structure, then the structure can begin to resonate, vibrating with harmonic oscillations driven by the energy of the flow. This vibration is the cause for overhead power line wires humming in the wind, and for the fluttering of automobile whip radio antennas at some speeds. Tall chimneys constructed of thin-walled steel tubes can be sufficiently flexible that, in air flow with a speed in the critical range, vortex shedding can drive the chimney into violent oscillations that can damage or destroy the chimney. Vortex shedding was one of the causes proposed for the failure of the original Tacoma Narrows Bridge (Galloping Gertie) in 1940, but was rejected because the frequency of the vortex shedding did not match that of the bridge. The bridge actually failed by aeroelastic flutter. A thrill ride, "VertiGo" at Cedar Point in Sandusky, Ohio suffered vortex shedding during the winter of 2001, causing one of the three towers to collapse. The ride was closed for the winter at the time. In northeastern Iran, the Hashemi-Nejad natural gas refinery's flare stacks suffered vortex shedding seven times from 1975 to 2003. Some simulation and analyses were done, which revealed that the main cause was the interaction of the pilot flame and flare stack. The problem was solved by removing the pilot. High Winds.

Strake is an aerodynamic surface generally mounted on the fuselage of an aircraft to improve the flight characteristics either by controlling the airflow (acting as large vortex generators) or by simple stabilising effect. In general a strake is longer than it is wide, in contrast to a winglet or a moustache. Leading edge root extensions (LERX) are also sometimes referred to as wing strakes.

Tapering is to become thinner or narrower towards one end.

Stack Effect is the movement of air into and out of buildings, chimneys, flue-gas stacks, or other containers, resulting from air buoyancy. Buoyancy occurs due to a difference in indoor-to-outdoor air density resulting from temperature and moisture differences. The result is either a positive or negative buoyancy force. The greater the thermal difference and the height of the structure, the greater the buoyancy force, and thus the stack effect. The stack effect helps drive natural ventilation, air infiltration, and fires (e.g. the Kaprun tunnel fire and King's Cross underground station fire).

Revolving Door typically consists of three or four doors that hang on a central shaft and rotate around a vertical axis within a cylindrical enclosure. Revolving doors are energy efficient as they (acting as an airlock) prevent drafts, thus decreasing the loss of heating or cooling for the building. Revolving doors were designed to relieve stack effect pressure in buildings. High-rise buildings experience immense pressure caused by air rushing through the building, referred to as 'Stack Effect' pressure. At the same time, revolving doors allow large numbers of people to pass in and out, and the door is always closed.

Airlock is a device which permits the passage of people and objects between a pressure vessel and its surroundings while minimizing the change of pressure in the vessel and loss of air from it. The lock consists of a small chamber with two airtight doors in series which do not open simultaneously. An airlock may be used for passage between environments of different gases rather than different pressures, to minimize or prevent the gases from mixing. An airlock may also be used underwater to allow passage between an air environment in a pressure vessel and the water environment outside, in which case the airlock can contain air or water. This is called a floodable airlock or an underwater airlock, and is used to prevent water from entering a submersible vessel or an underwater habitat.

Skyscraper Design and Construction involves creating safe, habitable spaces in very high buildings. The buildings must support their weight, resist wind and earthquakes, and protect occupants from fire. Yet they must also be conveniently accessible, even on the upper floors, and provide utilities and a comfortable climate for the occupants. The problems posed in skyscraper design are considered among the most complex encountered given the balances required between economics, engineering, and construction management. Keeping Skyscrapers From Blowing in the Wind - The New York Times.

Worlds Tallest Buildings (image)

Skyscraper is a large continuously habitable building having multiple floors. Modern sources currently define skyscrapers as being at least 100 metres or 150 metres in height, though there is no universally accepted definition. Historically, the term first referred to buildings with between 10 and 20 stories when these types of buildings began to be constructed in the 1880s. Skyscrapers may host offices, hotels, residential spaces, and retail spaces. One common feature of skyscrapers is having a steel framework that supports curtain walls. These curtain walls either bear on the framework below or are suspended from the framework above, rather than resting on load-bearing walls of conventional construction. Some early skyscrapers have a steel frame that enables the construction of load-bearing walls taller than of those made of reinforced concrete. Modern skyscrapers' walls are not load-bearing, and most skyscrapers are characterised by large surface areas of windows made possible by steel frames and curtain walls. However, skyscrapers can have curtain walls that mimic conventional walls with a small surface area of windows. Modern skyscrapers often have a tubular structure, and are designed to act like a hollow cylinder to resist wind, seismic, and other lateral loads. To appear slenderer, allow less wind exposure and transmit more daylight to the ground, many skyscrapers have a design with setbacks, which in some cases is also structurally required. As of January 2020, only nine cities have more than 100 skyscrapers that are 150 m (492 ft) or taller: Hong Kong (355), Shenzhen (289), New York City (284), Dubai (201), Shanghai (163), Tokyo (158), Chongqing (127), Chicago (127), and Guangzhou (118).

Hurricane-Proof Building is a variety of methods can help a building survive strong winds and storm surge.

Expansive Soils cause more property damage per year than earthquakes, floods, hurricanes, and tornadoes combined.

Soil Liquefaction occurs when a saturated or partially saturated Soil substantially loses strength and stiffness in response to an applied stress such as shaking during an earthquake or other sudden change in stress condition, in which material that is ordinarily a solid behaves like a liquid.

Sink Holes - Soil Mechanics - Erosion

Free Surface Effect is a mechanism which can cause a watercraft to become unstable and capsize. It refers to the tendency of liquids — and of unbound aggregates of small solid objects, like seeds, gravel, or crushed ore, whose behavior approximates that of liquids — to move in response to changes in the attitude of a craft's cargo holds, decks, or liquid tanks in reaction to operator-induced motions (or sea states caused by waves and wind acting upon the craft). When referring to the free surface effect, the condition of a tank that is not full is described as a "slack tank", while a full tank is "pressed up". Baffle is a flat plate that controls or directs the flow of fluid or energy.

New Earthquake Risk Model could better inform Disaster Planning. Researchers have developed a new way to model seismic risk, which they hope will better inform disaster risk reduction planning in earthquake-prone areas.